Cognitive System's technology helps you avoid logistical stress and profit loss by providing pertinent information to the appropriate personnel, thereby preparing your business for the future of machine learning, data analytics, and predictive maintenance. It is beneficial for various applications, from bearings on pumps to gearboxes on open-pit mining machinery.

Rotating Electric Machinery is crucial for uninterrupted operation in power, production, and process plants. Faults related to electrical, mechanical, and process/load factors can affect vibration behavior. Identifying these faults is essential to prevent unexpected machinery failure and unplanned downtime, which could lead to significant HSE risks and profit loss if left undetected.

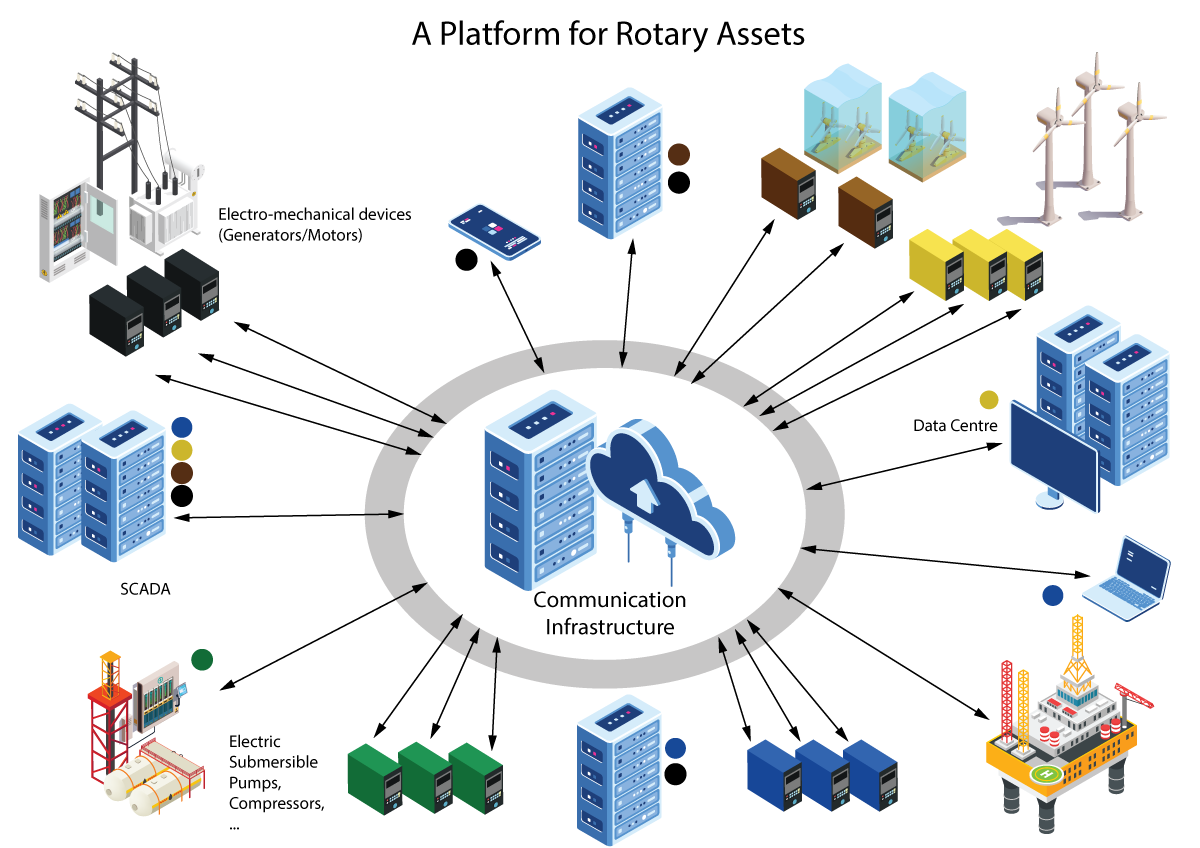

Solution: Cognitve Systems Inc. provide expertise and tehnology for optimization thorught full-life cycle of rotating asset.

By combining the power of high-fidelity data and in-depth domain knowledge, we help industries to reduce unexpected machinery failure, harmful effect of vibrations and energy consumption.

Our non-intrusive condition monitoring is well-suited for equipment in remote locations, such as electric submersible pumps, electric top drives, wind/tidal turbines, offshore and hazardous applications. Our proprietary technology allows us to extract and deliver high fidelity data and "Critical Operations Information" (COI) for technicians and engineers on site and over the cloud for data analysis, troubleshooting, monitoring and corrective intervention by team experts.